Next-Generation

Pressing Technologies for Clay & Building Materials

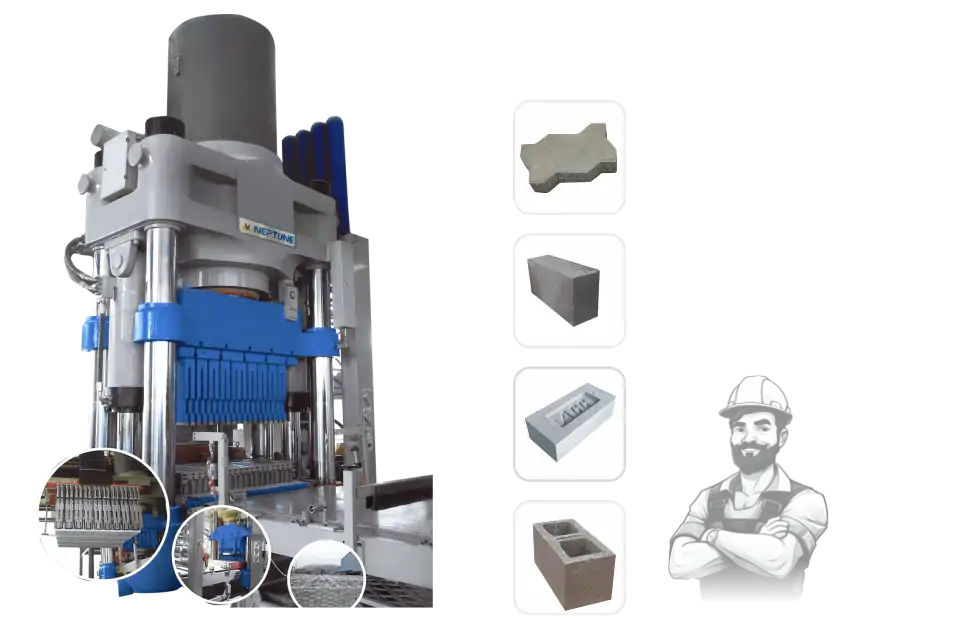

Advanced Pressing Technologies: UHDP for high-density Fly Ash products, Vibro-Compacting for bricks, blocks & pavers, and Table Pressing for Tap Hole Clay—each ensuring strength, precision, and consistent quality in production.

Machinery that manufactures Bricks, Blocks, and Pavers using UHDP Pressing technology.

UHDP Technology (Ultra High-Density Pressing): Our machinery, featuring 150 to 1600 Ton Hydraulic Presses, is designed to produce 10,000 to 4 Lakh Bricks per Day. Utilizing UHDP Technology, these machines offer high strength, precision, and durability. They also come with eco-friendly solutions, promoting sustainability in the construction industry.

Advanced Pressing Technology for Tap Hole Clay Production

Neptune’s Table Pressing Tap Hole Clay Machine is a fully automated THC plant with PLC-SCADA controls. It ensures consistent compaction, high-strength clay logs, and efficient production—ideal for blast furnace sealing and molten metal flow control.

Revolutionizing Block Making with Vibro-Compacting Pressing Technology

Neptune offers advanced servo-type Vibro-Compacting Pressing Technology for Bricks, Blocks & Pavers. With 5,000–2,00,000 units/day capacity, it ensures optimal compaction, high strength & precision for superior construction quality.